Features and benefits

High-speed system processes up to 52 units per minute.

Full range of pouch sizes from 8 to 20 inches (203 to 508 mm).

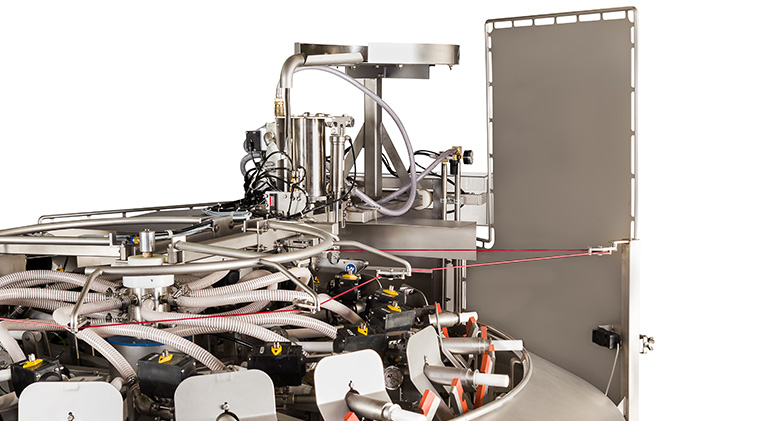

Configurable with 8 or 16 rotating vacuum nozzles, depending on production needs.

The packaged bags ensure high tightness in every cycle.

Numerous safety features enhance operator protection.

Simple and efficient design ensures reliability and ease of maintenance.

Hygienic design ensures uniform cleaning and meets international standards.

Corrugated Teflon vacuum probes ensure long-lasting performance.

The JBT TIPPER TIE PRoCARE system is available.

Details

Applications: Whole poultry carcasses, whole meat, cheese blocks, fresh minced meat and sausages.

Equipment options

Rota-Matic I: Designed for poultry.

The tilted table ensures uniform bag sealing by using gravity to center the poultry.

Rota-Matic III: Designed for packaging pork shoulders, fresh minced meat pieces, rings, blocks, hams and whole hams, cheese and poultry products.

Flat table.

Both models can be ordered as Super Rota-Matic.

Ideal for products with large cavities.

Large vacuum nozzles and an optional second pump allow for faster evacuation of air, resulting in higher production speeds.