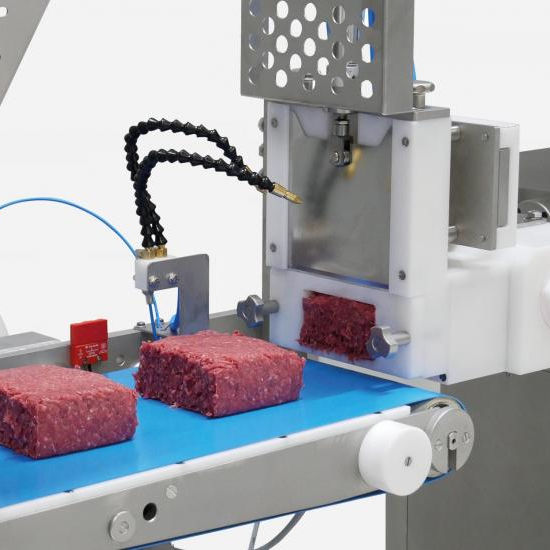

Directly connected to the vacuum filler, it shapes the product into different block sizes, cuts them into portions and deposits them on the conveyor belt. By means of a shaping roller at the end of the conveyor belt, the portion can be perfectly shaped into the meatloaf.

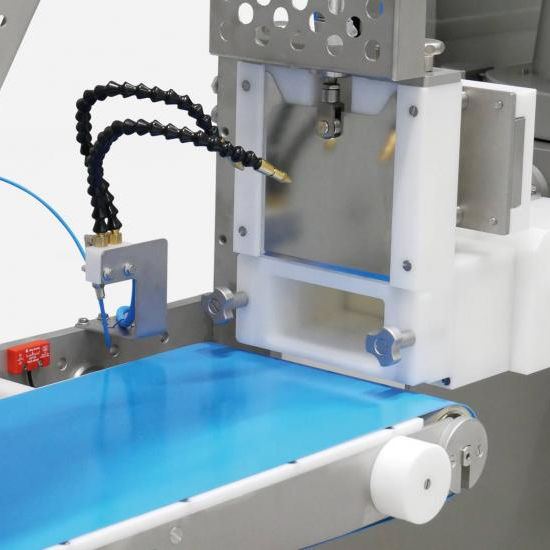

The pneumatic form cutter is mounted on the conveyor belt, the form inserts are exchangeable. The belt speed is infinitely variable.

Optional UV sterilisation for the conveyor belt guarantees the highest possible level of bacterial eradication thus enhancing hygiene standards, giving machine suitability in high risk environments.