Features and benefits

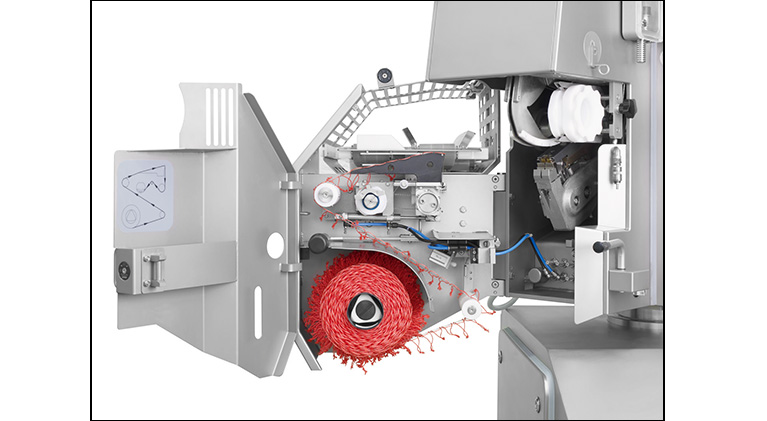

TT1512 for 20-80 mm and TT1815 for 35-140 mm.

The machine is made of durable stainless cast steel.

Ergonomic, compact design for easy handling.

State-of-the-art construction elements ensure a long service life and minimize wear and tear.

Quick changeover to the next step thanks to the click-click feed system.

20 speed levels plus through feed for maximum productivity.

JBT TIPPER TIE PRoCARE system available.

Details

Applications: sausages and meat products, vegan products, fish, surimi/sausage paste, raw/frozen/chilled animal feed, cheese, soups, sauces, fruits/vegetables, industrial explosives packaging.

Electronic clip clamping control prevents machine damage and increases production reliability.

Equipped with a maintenance-free servo drive and SPS control.

Easy to operate via touch screen.

Smooth, sloped surfaces allow for quick, hygienic cleaning.

Valves, actuator and control unit are protected from water and dirt by covers.

Equipment options

Airless filling of molded products by expansion; total expansion 130 mm (TT1815).

Belt feeder for loops BSZ 105-2.

Thread dispenser for ring products.

Clip and loop end detection.

Adjustment of single clips.

Coding of clips.

TagPrint 60 labeling system.

Manage printable tags for centralized stamps.

Mechanical and optical portioning by length.

Swivel, V-head or parallel turret heads.

Conveyor outlet, chute in various versions.

Pneumatic braking mechanism for sensitive casings.

Sheath end detection.

Wheel stop for easy maneuvering.