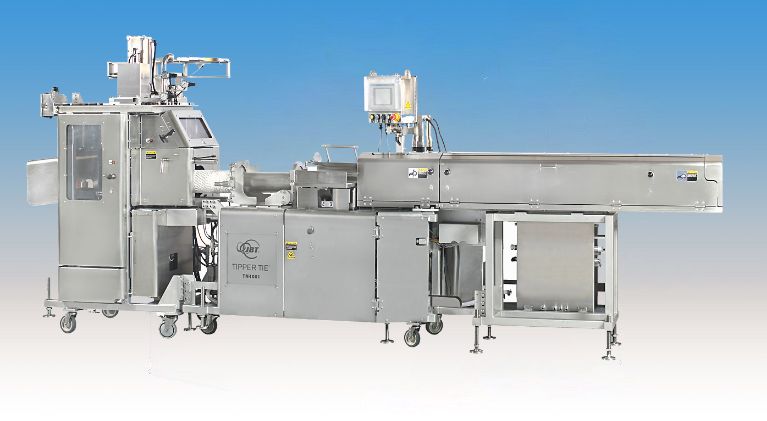

Features and benefits

Reduced labor costs by using one operator per machine.

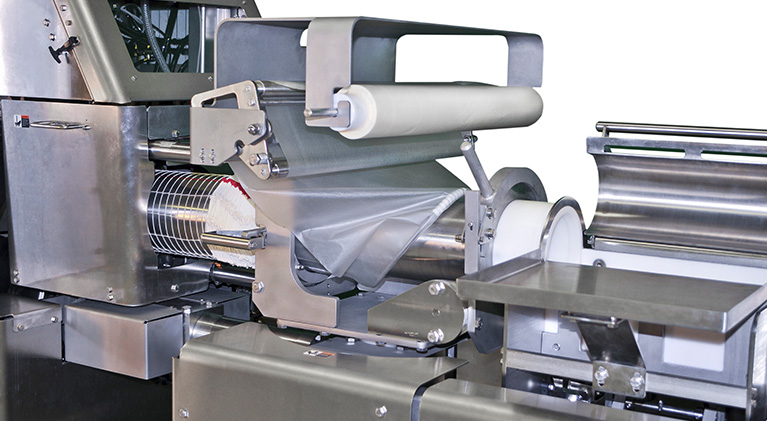

330 mm manual force-assisted closure for pressing product into the package.

Speed: 11-13 units/minute.

Use of servo drive technology to reduce overall maintenance costs, energy consumption and noise levels.

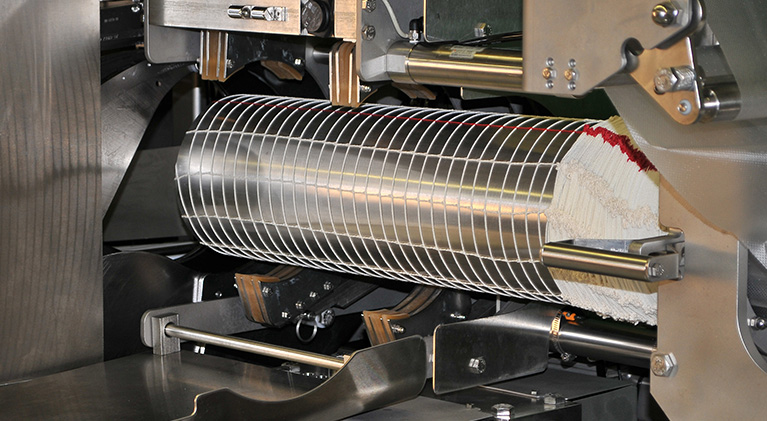

Mesh processing with or without collagen film or sheath.

The JBT TIPPER TIE PRoCARE system is available.

Details

Applications: sausages, ham, whole muscle meat, netted meat and poultry, vegan sausages and vegan ham.

Servo-driven mechanism for product feeding.

Programmable initial, main and final conveyors: their speed and movements can be precisely adjusted by the operator to achieve greater product uniformity.

Equipment options: quick change of locks in various sizes from 3 to 8 inches (76-203 mm) is possible in 15 minutes. A looper is available to securely attach a cord for suspended products.