The new TIPPER TIE TN 3004 system sets new standards for performance and reliability. The TN 3004 is ready for maximum automation and can be loaded by robotic systems to minimize human interaction and reduce the risk of Covid-19 infection.

Thanks to an improved reject program, the TN 3004 delivers higher productivity without the need to increase the speed of operation, which leads to rapid wear and tear on parts. The updated conveyor system, together with advanced software, allows processing up to 12 products per minute without excessive machine wear. High-torque multi-pole motors replace the old pneumatic motors, providing better control and reducing the need for compressed air.

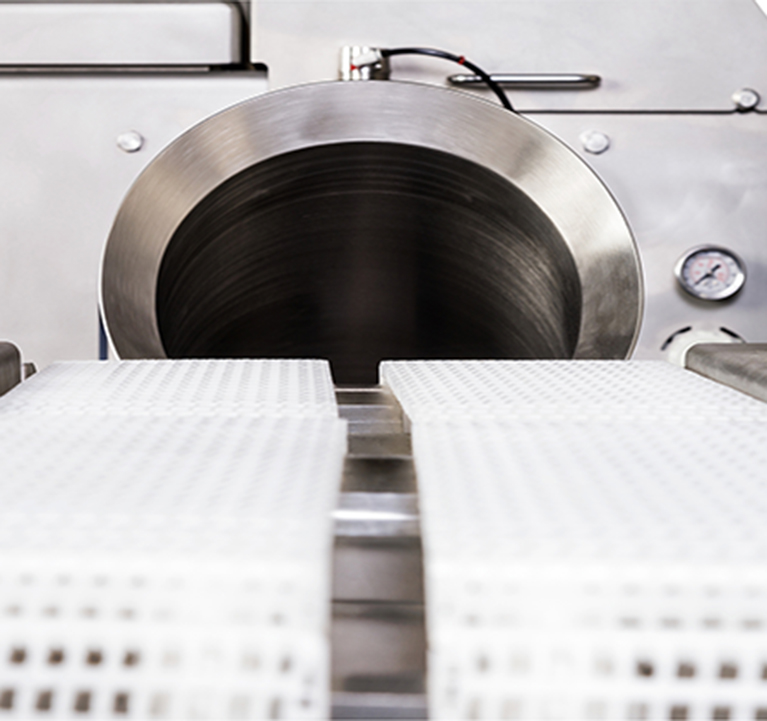

The TN 3004 utilizes a new all-metal design that provides better access to work areas for easier and more efficient cleaning. The absence of enclosed pipes and hidden areas that could previously have been breeding grounds for microorganisms is another advantage.

Our Always Aligned printer system allows for quick removal of the printer during cleaning and ensures it is precisely aligned when reinstalled, eliminating the need to pack it away during cleaning and reducing the risk of damage. The TN 3004 also features an advanced labeling system. This new system, which incorporates Sigma IPC and LabelPak software, uses the Encompass.net management interface to allow for the control of multiple systems from a single location. The system also features an automatic sorting function that allows products to be sorted continuously, increasing order fulfillment efficiency. Whether you’re fulfilling orders with multiple machines or processing multiple orders on a single machine, the TN 3004 is fully equipped for the task.

Features:

Automatic handle forming system.

Automatic netting system.

Automatic double clip system.

Built-in printer or marker (optional).

Allen Bradley controllers.

Electric feeding system with conveyor.

Requires only one operator.

Made of stainless steel and other non-corrosive materials.