Features and benefits

Automatic production.

An operator or robot places the product on the conveyor and the TN 2004 does the rest, ensuring that each product is evenly netted and closed.

Increased productivity.

Automatic tray change allows you to move an empty tray to the buffer and a full tray to the working position without wasting time.

More productivity.

Electric high-speed servo drives provide unrivaled product control, faster travel speeds, proven reliability and minimal maintenance requirements.

New hygienic frame design.

No enclosed hoses or hard-to-reach areas, allowing for quick and efficient cleaning during sanitation.

Electric feeding conveyor.

The electric drum-type motor can be adjusted in speed, unlike pneumatic motors that only have an on/off mode.

Easy maintenance.

Few parts and no complicated drives make the machine easy to maintain and reliable.

Available in right- and left-handed versions.

The TN 2004 is available as a right- or left-handed machine to fit any production layout.

Machines can be arranged so that one belt serves two machines.

The JBT TIPPER TIE PRoCARE system is available.

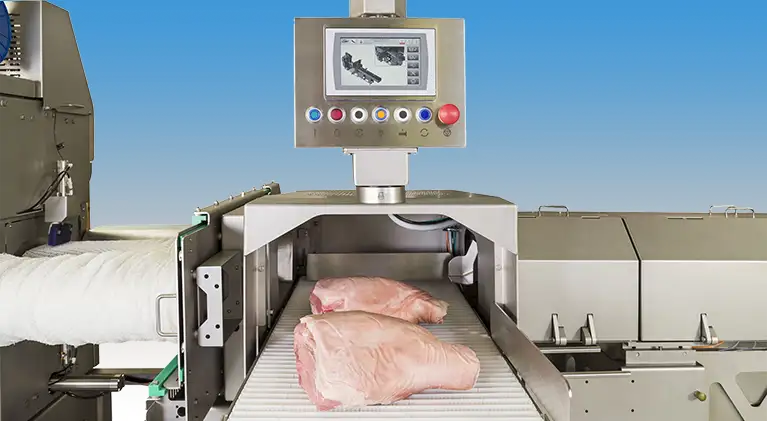

TIPPER TIE TN 2004 netting and clipping system

Price - On request

The new TIPPER TIE Netter TN 2004 automates the netting and clipping of products such as large bone-in hams, small breasts and formed products. Its innovative design ensures high system performance, significantly reduces labor costs, increases productivity and saves on netting materials while improving product quality and consistency.

| Brand | JBT TIPPER TIE |

| Working width (mm) | 5280 mm [208″] |

| Глибина | 1750 мм [68,75″] |

| Висота | 1925-2025 мм [75,75″-79,75″] |

| Швидкість | 12 шт./хв (Старт-Стоп) |

| Supply voltage | 400/480 В, 30 ампер |

| Тип кліпси | Z321 |

| Довжина жолоба | 683 мм (26,875″) |

| Клас захисту | IP65 |

| Витрата повітря | 15 SCFM при 12 шт./хв |