Guaranteeing the high quality of plastic crumb and recycled materials is critical to determining whether plastic recyclers and manufacturers can profitably use and sell plastic recyclables.

Depending on how the recyclables will be used, and as a means of evaluating the sorting process of recyclables, thorough manual, visual or thermal analysis of samples is often required to assess the quality of a batch of materials.

Such sample analyses are hardly representative and require additional resources, costs and time.

With the FLAKE SCAN analysis system, you can accurately determine the quality of plastic crumbs and re-grind them in just a few minutes. FLAKE SCAN virtually eliminates the need for time-consuming sample analysis and significantly reduces the effort associated with manual, visual and thermal inspection.

By providing fast and informed decision-making on the viability of plastic crumbles and recycling, FLAKE SCAN helps to increase the profitability of plastic recycling. In addition, the results provide valuable insights into the recycling process and the functionality of various components.

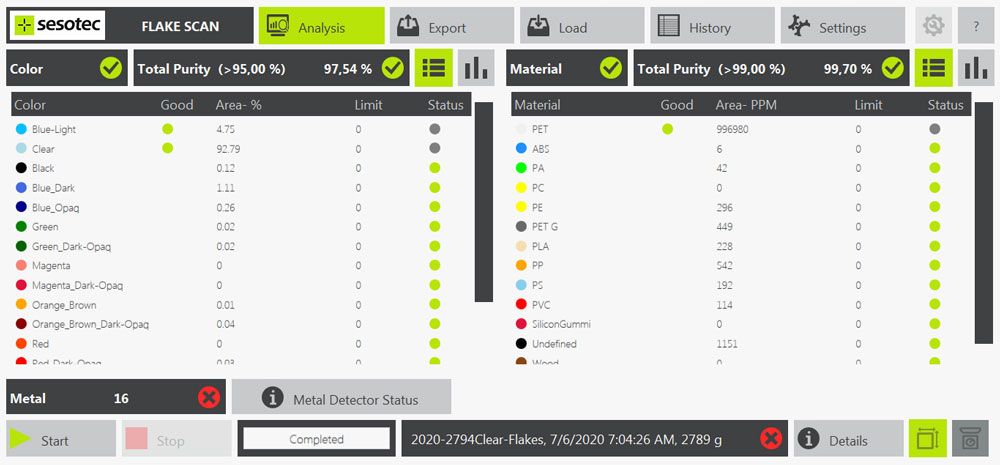

The results of the analysis can be displayed in a table or diagram. In case of exceeding the set limits for polymer types or false colors, this will be indicated in the table. The amount of metal impurities detected will also be shown.

Saving data

From the History menu, you can quickly compare the purity and color quality of the current batch with the same indicators of archived samples.