Features and benefits

With the benchmark versatility and productivity of the SVU6800 and the introduction of the quiet and efficient mechanical design of the SV4800 and DCSV5000, TIPPER TIE has set new standards for large clippers.

The machine can process products with diameters from 50 to 120 mm and can be optionally equipped with a SlackFilling device for calibers up to 300 mm.

With a first-class start/stop speed of up to 65 pieces per minute, the SVU6800 is a particularly fast machine.

The clamping system has a simulated shock absorption function to protect sensitive shells and an overload protection to prevent damage to the machine.

ZR400 series clips are used for medium to large products in particularly thick casings, and E400 series clips for medium to heavy hanging products.

The hinge feeder is capable of handling 45 hinges per minute and can be installed on the conveyor side or in front of the filling tube, depending on the space available in the production area.

The SVU6800 allows for the suspension of heavy products using the BF series hinges, available in 3 or 4 layers.

The optional PRK 2-tube turret is another option for increased productivity.

The parallel turret significantly reduces downtime for casing changes, which increases daily output.

The JBT TIPPER TIE PRoCARE system is also available.

Details.

With the SVU6800, the focus is on maximum uptime and low operating costs.

Long maintenance intervals are a top priority.

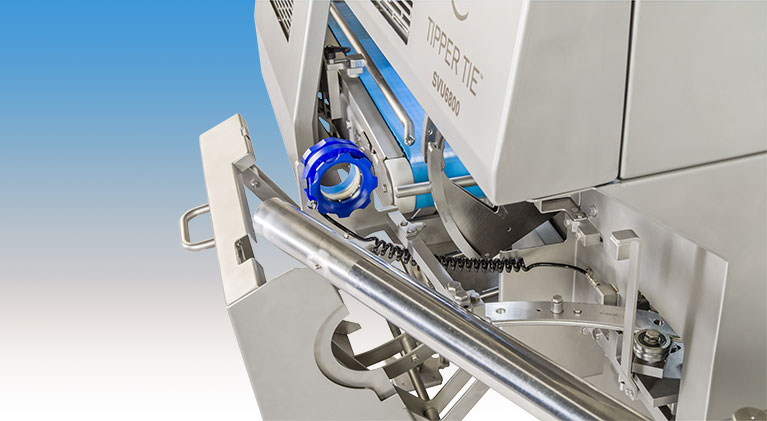

The SVU6800 utilizes cam rollers that are significantly larger than before, as well as hardened rollers for the most critical travel and clipping tasks.

The SVU6800 has been designed with a special emphasis on hygienic efficiency and ease of maintenance.

The direct-drive motor eliminates the need for belts and chains, thereby minimizing potential weak points and preventing hygiene risks that arise when belts or chains are used in the vicinity of products.

Thanks to its centrally located lubrication points, the SVU6800 is very easy to maintain, ensuring long and trouble-free operation.

All exterior surfaces are smooth, easy to clean and sloped to prevent water accumulation.

Easy-to-access safety features on the front and rear make it easy for mechanics to diagnose problems and make repairs.

Equipment options

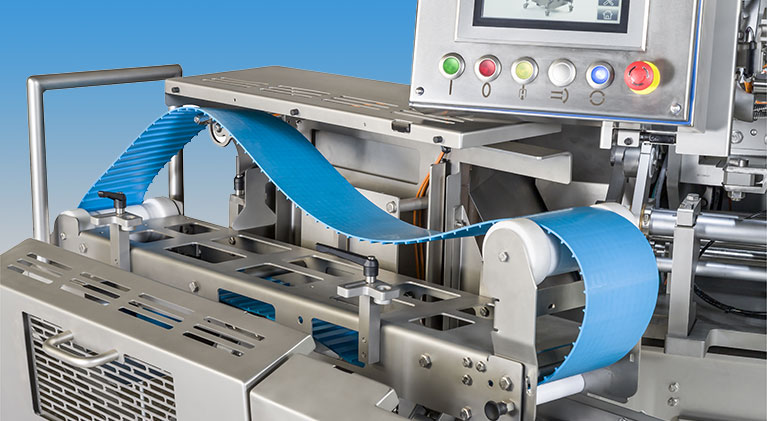

Loop feeder. In many processes, the product needs to be suspended for further transportation. For these applications, the SVU6800 is equipped with a loop feeder that fills during the clipping process.

The equipment is also designed for heavy products.

The loop feeder can be configured either at the front or at the back of the production line depending on the existing production processes.

Speed

Speed: up to 45 loops/min.

Options

Filling tube mounting: The SVU6800 can be equipped with an easy-to-clean rotor with a diameter of 60 or 100 mm.

The S-shaped brake mechanism facilitates shell changes and increases productivity.

The optional PRK system with two revolvers reduces downtime to a minimum and is suitable for filling tubes up to 756 mm in length.

SlackFilling system: Additional processing options include special product shapes, such as D-shaped or square.

The optional vacuum system for the filling tube enables the production of dense, airless products.

Other options

Additional options include registration for labeling, a length gauge, switches for the end of the shell, LED lighting and Siemens or AB control systems.

Numerous filler tube sizes up to a diameter of 100 mm are available to meet the individual requirements of each customer.