Features and benefits

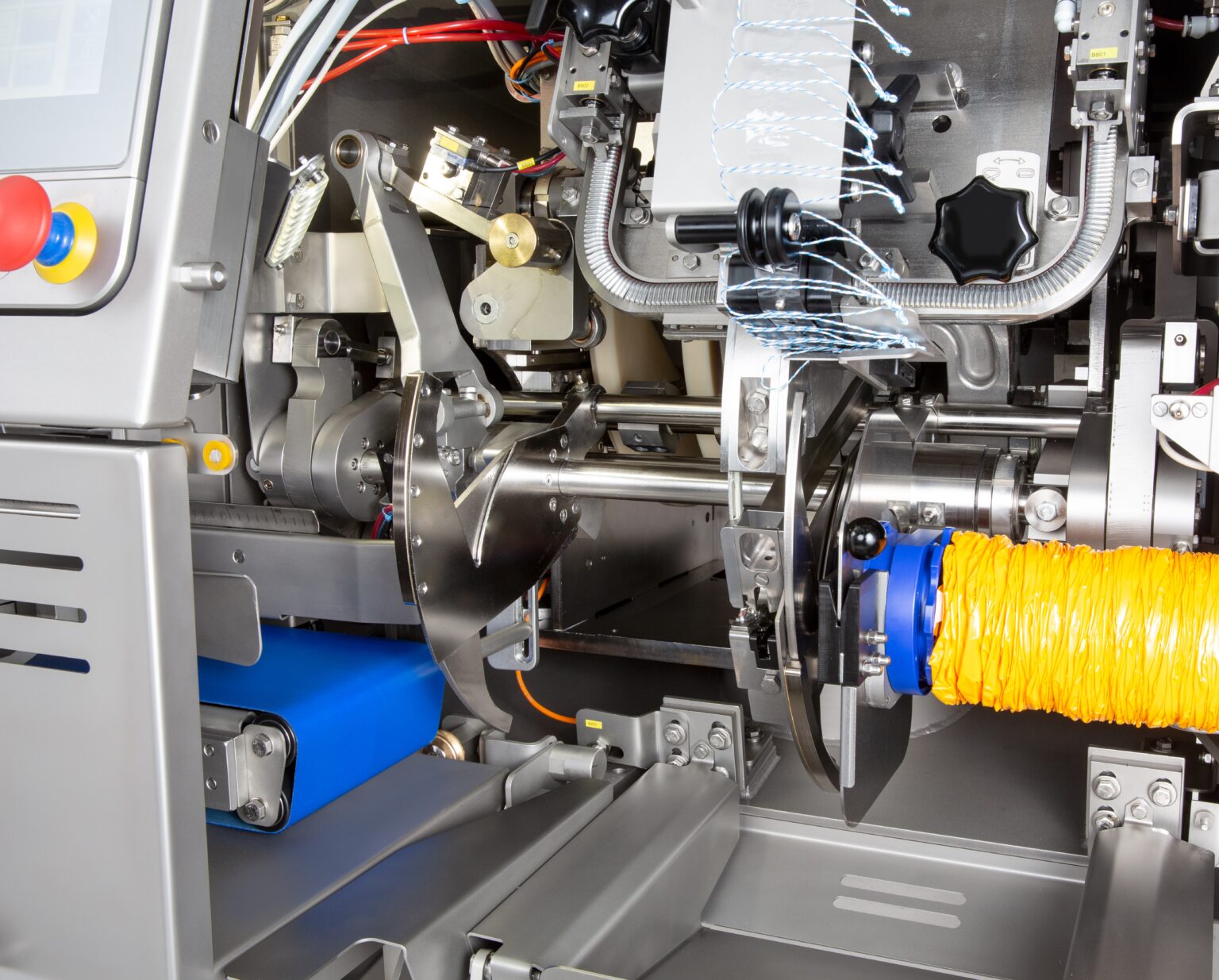

The fastest and quietest U-clip expander, capable of processing up to 120 servings per minute.

The speed is adjustable in six levels and can be adapted to any product.

Robust design with modular structure at the customer’s request.

Easy to maintain and repair.

The JBT TIPPER TIE PRoCARE system is available.

Details

Applications: sausage, sausage products, ham, whole meat cuts, vegan and vegetarian products, fish, surimi/fish paste, raw/frozen/chilled pet food, cheese, soup, sauce, fruits and vegetables.

The clip extension system allows processing ham products with any artificial casing available on the market up to 160 mm in caliber.

The clip clamping control prevents damage to the machine in case of incorrect manipulation.

A rotary casing brake mechanism allows for quick casing changes without moving the clipping head, minimizing downtime and maintenance costs.

The rotary output conveyor ensures the supply of calibrated products thanks to the programmable and continuously variable conveyor belt speed.

Smooth, non-corrosive surfaces, excellent access to all areas and sloping horizontal surfaces ensure fast and hygienic cleaning.

Equipment options

Shell expansion device for airless filling up to 250 mm.

The rotating turret with dual horns maximizes productivity and allows for case changes with virtually no downtime.

The TD60 labeling system is ideal for precise product identification.

TeQu-S belt hinge insertion.

Telescopic conveyor.

Portioning by length with optical control.

Extension tube for filling.

Clips on the coils.

Switch to control the end of the shell.

Start-stop button at the end of the conveyor.

SV4800 side ejection configuration for customers with limited space or for very long products.

SV4800 Double automatic clipping machine

Price - On request

The SV4800 from TIPPER TIE is the ideal clipping system for sausage and molded products in calibers from 45 to 160 mm. All known synthetic, fiber and collagen casings are processed quickly and reliably.

| Brand | JBT TIPPER TIE |