Features and benefits

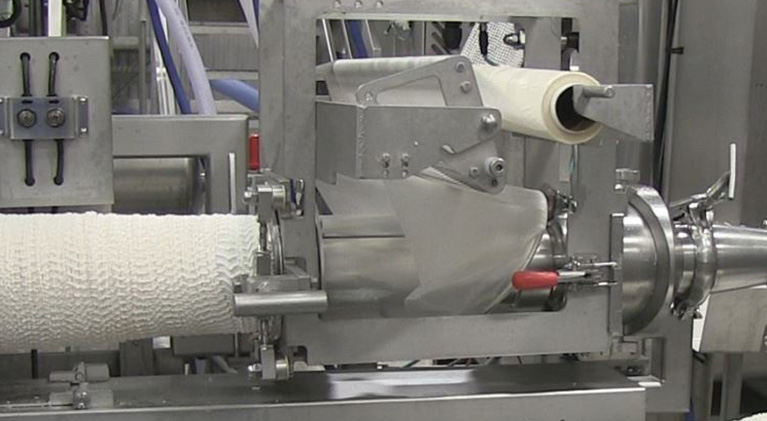

Processes products with a diameter of 50-280 mm.

Durable stainless steel construction.

Short setup time thanks to intuitive operation.

Available with JBT TIPPER TIE PRoCARE system.

Details

Applications: sausage, sausage products and ham, fresh, chopped meat, whole muscle meat, netted meat, meatless sausages, ham and sausage products, fresh, chopped fish, surimi/fish sausage paste, raw/frozen/chilled animal feed, liquid cheeses, soups, sauces, chopped fruits and vegetables.

The highly resistant and stable displacement system ensures that products of different consistencies can be processed without any problems.

The damping in the end position ensures that sensitive membranes are evenly clamped.

A portion length limiter ensures precise filling to a repeatable length, which increases product yields and reduces the need for rework.

The touchscreen user interface, supported by a sophisticated color display, provides easy programming and operation.

The operating system stores an unlimited number of recipes for quick product changes.

The diagnostic system allows you to monitor each individual stage of operation, if necessary.

Equipment options

Includes inserts for hinges.

Mirrored machines allow the operator to operate several machines simultaneously, which reduces costs.

The RS4204CM (Collagen-Model) is equipped to pack liquid pork and poultry products in collagen film and elastic mesh.

The Slack Fill System allows for the production of unique product shapes such as D-shaped or square.

The RS vacuum system ensures tight, airless packaging of products.

In addition, numerous tube sizes up to 100 mm are available to meet individual customer requirements.