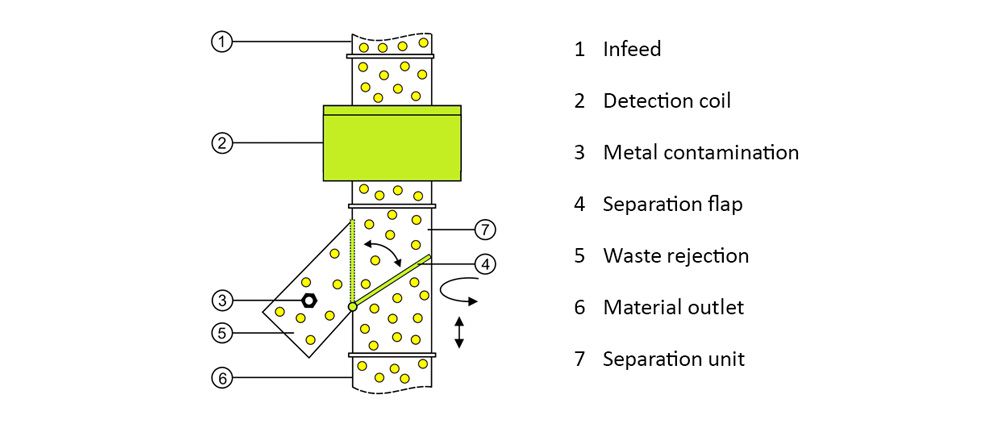

RE-SORT For plastics manufacturers and processors, the loss of pellets in production means reduced productivity and a further impact on the environment. The RE-SORT metal separator reliably removes metal particles from plastic pellets that have already been removed from the production process. The processed product can be returned to the material flow. Main advantages. Recovery rate up to 98%. Resource saving and economic efficiency Main features: Detects and separates magnetic and non-magnetic metal contaminants in heavily contaminated material. Pellet production and compounding. Plastics processing, especially in in-line processing. Recycling industry. Chemical industry

Related products

-

LIQUISCAN VF+

Metal separator for filler...

Price - On request More about product -

RAPID PRO-SENSE

Highly efficient metal separator for free-fall...

Price - On request More about product -

GLS

Metal detector for installation in conveyor systems – Basic model with single/dual frequency technology Perfect adaptation to specific customer requirements thanks to the closed system with...

Price - On request More about product -

VARICON+ GLS MF

Metal detector for conveyor belts - standard model with multi-frequency...

Price - On request More about product