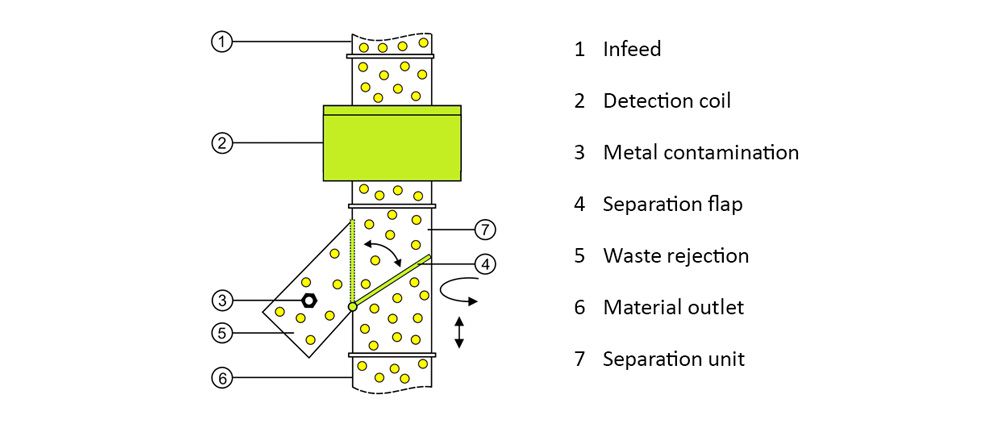

The RAPID PRO-SENSE metal separator is primarily used for quality control (product purity) in the production and mixing of plastic granulate, where it is usually installed just before filling the material into bags, octabins or silos. The metal separator is also used for quality control in the incoming goods department at plastics processing plants (product purity, machine protection). Feeding. Detector coil. Metal contamination . Separation flap. Waste rejection. Material outlet. Separation unit (swivel, removable) Function The RAPID PRO-SENSE metal separator is used to monitor bulk materials in free-fall conveyor tubes. It detects and separates all magnetic and non-magnetic metal contaminants (especially stainless steel, aluminum, non-ferrous metals, …) – even if such contaminants are contained in the product. The rejection unit reliably separates metal contaminants from the material flow. The RAPID PRO-SENSE metal separator is primarily used for quality control of bulk materials in the plastics and compounding industry. Highest scanning sensitivity for all metals thanks to innovative HRF (High Resolution Frequency) technology Modular system design for optimal adaptation to customer requirements and specific materials. Auto-learning function or manual product influence compensation for optimal compensation of the intrinsic conductivity of the inspected material Automatic cleaning systems The low installation height, even with a large nominal width, guarantees easy integration of the metal separator into existing piping systems. Quick and easy installation thanks to standard Jacob connections. Increased interference protection against electrosmog and vibration. Exceptional ease of operation with the GENIUS+ control unit with graphic LCD display. Metal components in contact with the product are completely made of stainless steel 1. 4301 (AISI 304)

RAPID PRO-SENSE

Price - On request

Highly efficient metal separator for free-fall applications

Related products

-

RE-SORT

Metal separator for material...

Price - On request More about product -

RAYCON EX1

The entry-level model for packaged...

Price - On request More about product -

ELCON

The ELCON single-sided metal detector is used for inspection of fine and loose materials on conveyor belts or chutes, preferably with low material heights. It detects all magnetic and non-magnetic...

Price - On request More about product -

RAPID PRO-SENSE 6

Highly efficient metal separator for resin and compound...

Price - On request More about product