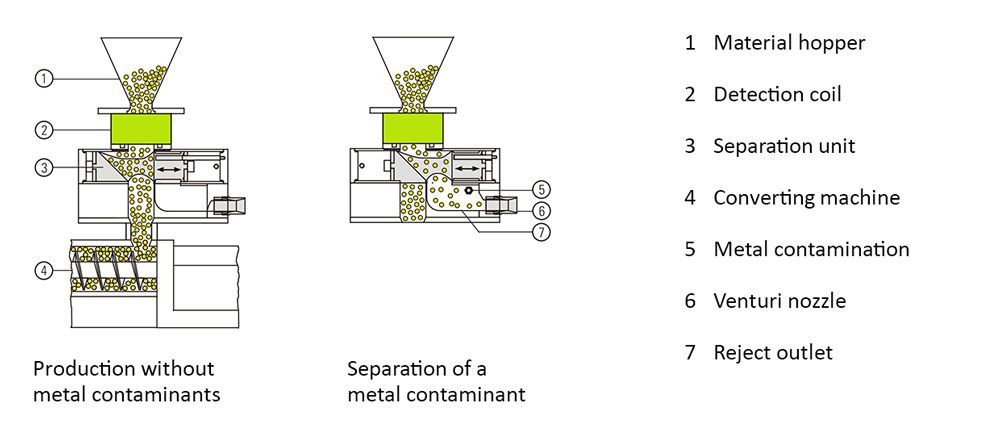

Small metal particles in the melting process of plastics often lead to costly breakdowns of injection molding machines, extruders and blow molders. The amount of such metal contaminants increases during the processing of regranulate and shredded raw materials. As a result, clogging of nozzles, filters and hot runner systems can lead to production downtime and delivery delays. The PROTECTOR metal separator is installed directly above the feeder of an injection molding machine, extruder or blow molding machine. It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminum, etc.) – even if they are contained in the product. The metal contaminants are ejected through the Quick-Flap separation unit.

PROTECTOR

Price - On request

Metal separator for extruders, injection moulding and blow moulding machines

Related products

-

GLS

Metal detector for installation in conveyor systems – Basic model with single/dual frequency technology Perfect adaptation to specific customer requirements thanks to the closed system with...

Price - On request More about product -

UNICON+

Metal detection system for individual...

Price - On request More about product -

RAPID 6000

Metal separator for free fall of coarse or flaky...

Price - On request More about product -

VARICON+ GLS

Metal Detector for Conveyor Belts - entry-level model with single/dual frequency...

Price - On request More about product