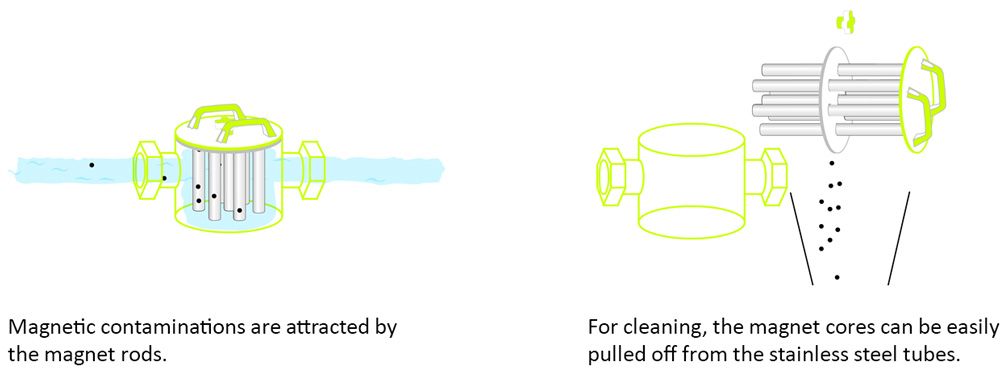

Quality and quality control play an important role in the food industry. It is important to use the latest technology for processes in food production. LIQUIMAG magnetic separators are designed to meet all the requirements and standards of the food industry (e.g. IFS, HACCP). The magnet filters can be easily integrated into existing pipelines transporting liquid or paste-like products. Low maintenance and easy cleaning of the magnetic separator guarantee efficient and trouble-free operation. Features of the LIQUIMAG filter magnet: – Optimal separation of magnetic contaminants is guaranteed due to the high magnetic flux density of 1,370 mT (13,700 gauss) and the alignment of the magnetic rods. – Even slightly magnetized stainless steel particles can be separated – all models are equipped with the EASY CLEAN option. They are maintenance-free and can be cleaned quickly and easily. – Suitable for CIP (clean-in-place) and SIP (sterilize-in-place) applications. – For applications where only heated products can be transported, a version of the LIQUIMAG is available with a double-walled filter housing that can be heated with water. The high-intensity neodymium magnetic material can be used at temperatures of up to 100°C. For higher temperatures, a special samarium-cobalt material can be used. Typical applications: – Food industry: butter, oils, sauces, chocolate, jam – Chemical industry: coolant, hydraulic fluid – Pharmaceutical industry: preservatives, saline (medicine)

LIQUIMAG

Price - On request

Filter magnet for liquid and pasty products

Product characteristics