Features and benefits

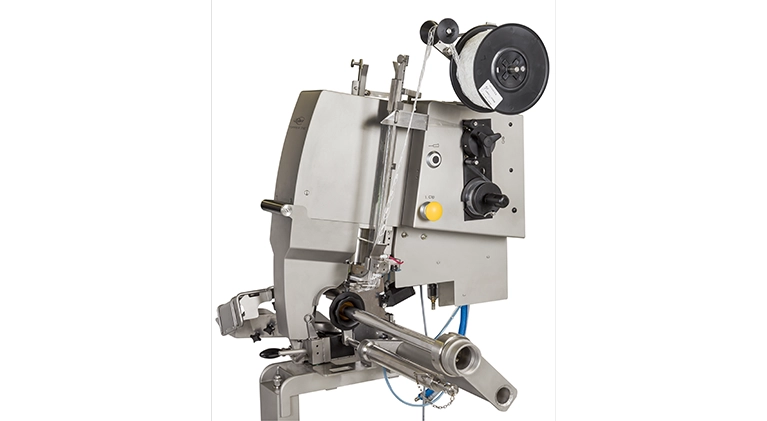

Suitable for calibers from 25 mm to 120 mm.

Robust construction with modular design to meet customer requirements.

Hygienic design: beveled and smooth surfaces, easy cleaning thanks to good access.

Single-acting cylinders with low air consumption.

Ergonomic tilt of the machine for better handling and visibility of the production area.

Wide range of optional equipment.

JBT TIPPER TIE PRoCARE system available.

Details

Application

Sausage and meat products, vegan products, fish, surimi/sausage paste, raw/frozen/chilled pet food, cheese, soup, sauce, fruits and vegetables, as well as sealant and adhesive products.

The adjustable shell brake prevents overloading and ensures precise portioning.

Convenient operation via touch screen with 50 saved programs such as stop counter, number of servings per minute, system settings menu, machine switch menu, error log, product setting position error, hinge test, label test and start filling indication.

The stainless steel components with angled surfaces and the innovative design with free-suspended locking plates meet the highest hygiene requirements.

Single-acting cylinders in the clip clamping area increase machine speed and significantly reduce air consumption, thus providing economic benefits.

Four robust shear plates ensure reliable processing of all common types of casings.

Equipment options

Support sheet for ring and stick products.

Discharge roller conveyor belt for stick products.

Label insert with printer for labeling products. Reel system to reduce clip reloading time.

Thread dispenser for the production of ring products.

Optical (adjustable) length limiter to reduce waste during cutting.

Automatic looping machine – products can be hung on loops during the production process or for product presentation.

Electronic counter.

ChatG