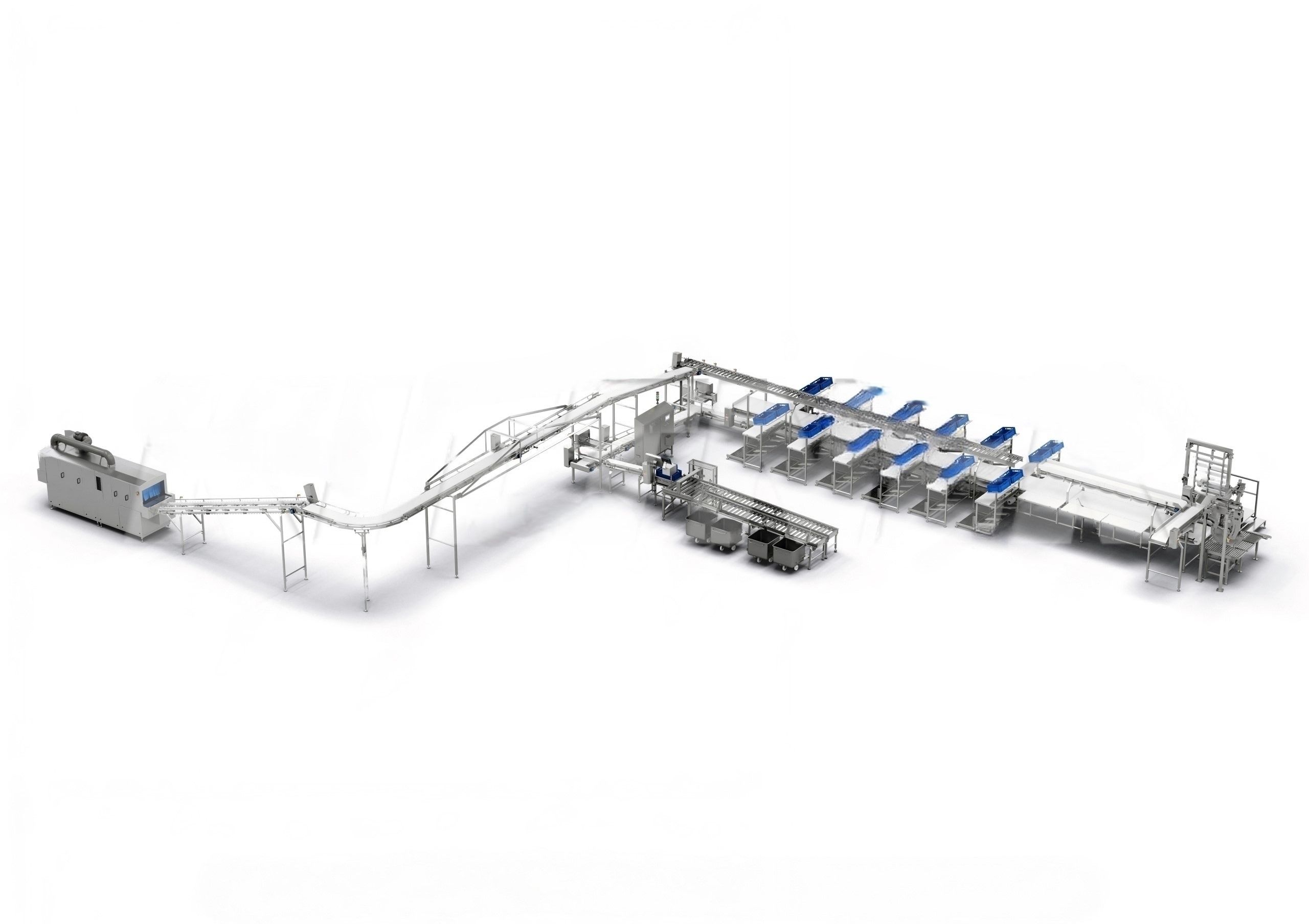

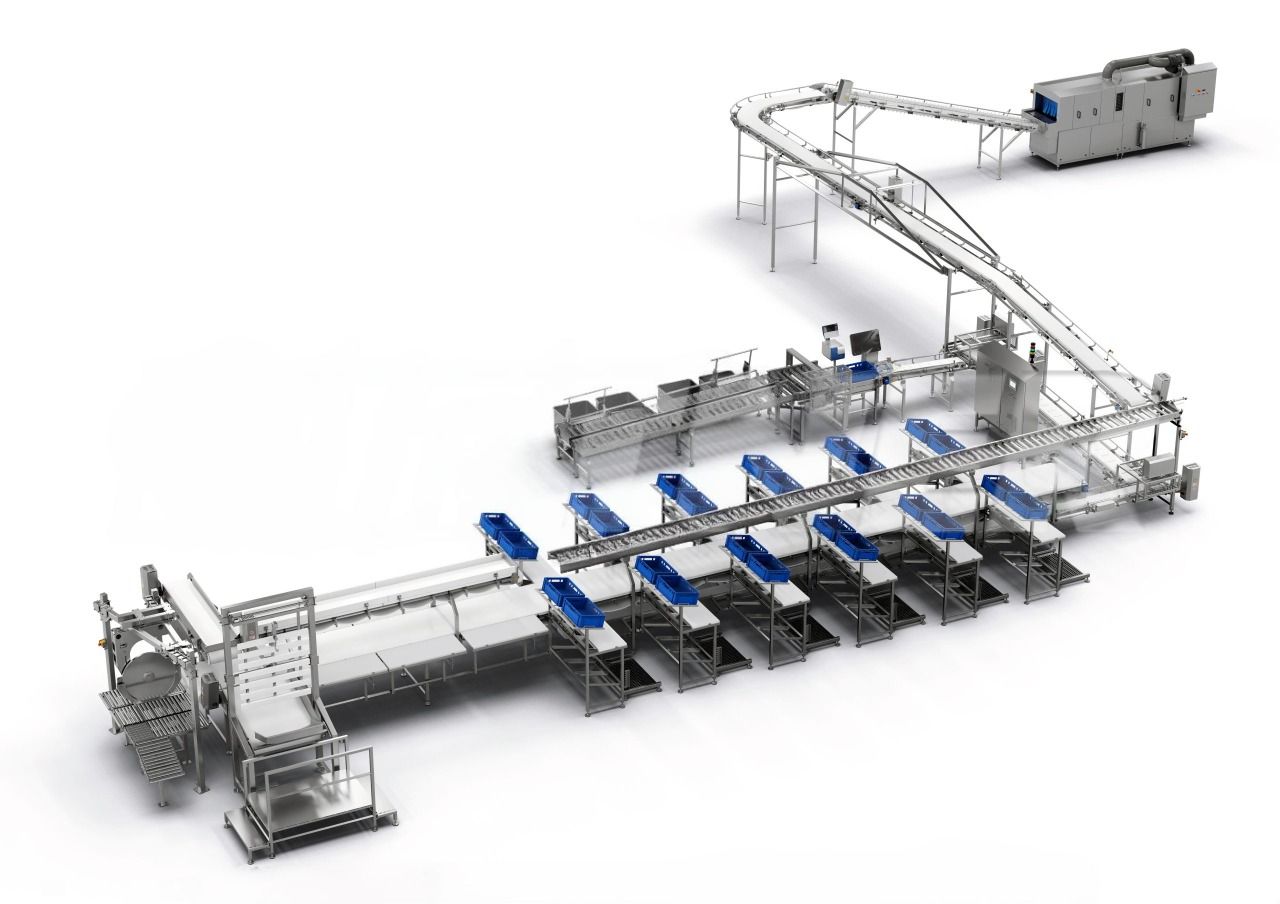

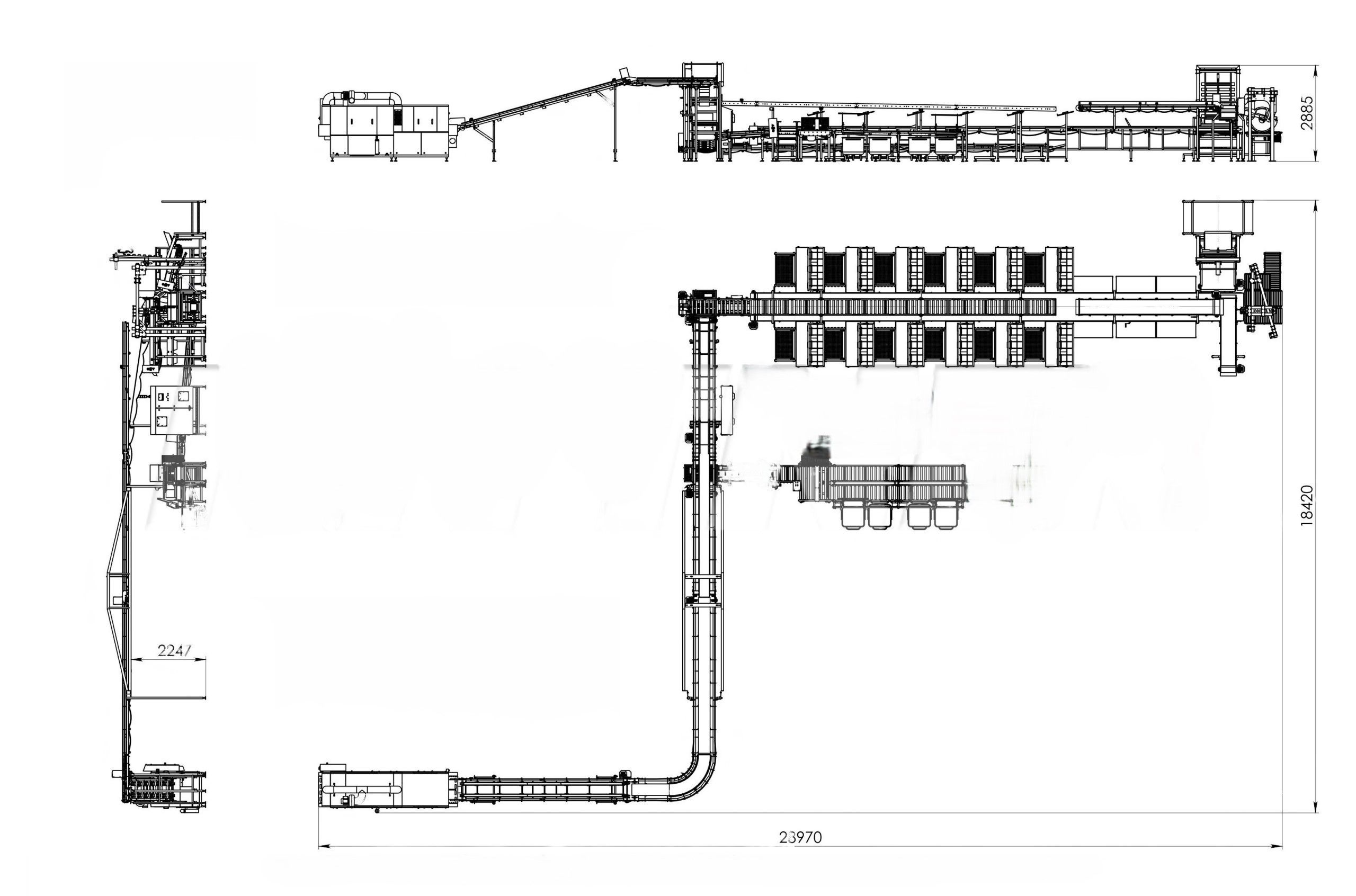

The meat cutting line is designed to process up to 25 tons of meat/shift. The pork halves are fed to a circular saw via tubular rail system and the beef quarters to a pneumatic platform for primal cutting. After primal cutting, the meat cuts are transported to 6 parallel tables for deboning, where the bones are separated and transported by special conveyor and the boneless meat is transported by conveyor belt to 12 perpendicular cutting tables for fine-cutting and sorting by type and quality. The crates full of meat are transported to the i-point, where they are weighed, labelled and then taken for further processing of the meat or for freezing. The cutting line has belt conveyors on four levels transport of full crates, transport of pork/beef meat and transport of bones and empty crates. The meat cutting line is supplied with clean crates by a clean crate conveyor and a crate washer. It is made of 1.4301 stainless steel, has a robust and reliable construction, hygienic and ergonomic design, ensuring safe operation of the personnel. The automation and control of the processes in the line are realized by the latest generation PLC Siemens and intuitive touch screen display.

Deboning line for pig halves and cattle quarters

Price - On request

| Power | 8 kW |

| Power supply | 400 V 50/60 Hz |

| Brand | Kittner |

| Ambient temperature | 24 V DC |