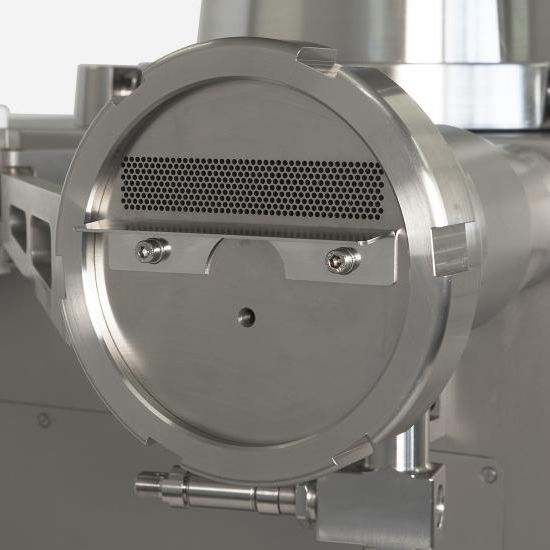

The end piece of the MC 3-3 can be individually equipped to suit the size and shape of the product. Product widths with different grain sizes are possible – from 60 to 220 mm. The design of the end part in the form of special grids allows you to produce portioned products of a given shape, for example, kebabs and croquettes (several pieces in a row) with a lining on paper.In the process of producing portioned minced meat, grinding plays an important role. Pre-ground raw materials are precisely portioned with a syringe, and the combination of the grinder with the MC 3-1 and MC 3-3 attachments brings the grain and portion size to the required parameters. The cutting speed of the whisk drive can be adjusted to create the desired minced meat pattern. The independent servo drive and the functions of the impeller attachment are controlled via the touch screen of the syringe control unit, and depending on the selected portioned product, the cutting speeds can be set to your liking. The RHP 240 portioning device completes the line. The device is connected to the filling syringe and the MC 3-3 wolf nozzle. The RHP 240 transports the mass of minced meat, dividing it into portions exactly according to the selected size.

Complete line solution MC 3-3 and RHP 240

Price - On request

The REX mincer portion line range developed by REX is designed to meet all industrial requirements. The modular system is quick and easy to adapt to a customer’s specific requirements. This makes the REX minced meat line the most cost-effective line solution, without compromising the product quality.

Product characteristics