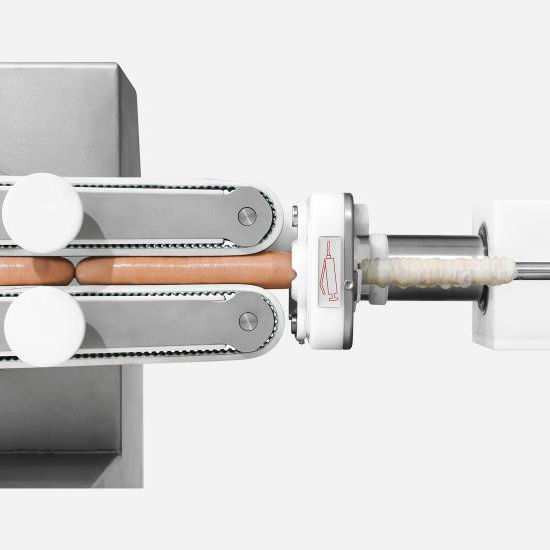

Calibration performs an important function in achieving the specified length and exact weight of the product. The RKS ensures an easy changeover from natural to artificial casing and vice versa, and is the basis for further process optimization. The product (sausages, frankfurters) is fed directly from the syringe casing holder onto the two conveyors of the RKS. This way, the twisting process is optimized as much as possible and product rejects due to casing breakage are reduced. The RKS conveyors are height-adjustable and can be adjusted to fit products of any diameter, ensuring a uniform weight and length output, which improves product quality and ensures compliance with the standard.nThe RKS calibration device is equipped with a servo drive that can be set and monitored on the touchscreen of the syringe control unit. The speed of the conveyors is automatically adjusted to the specific product and portion size, thus ensuring minimum changeover time.nThe product calibrated on the RKS can be fed directly to the RHS sausage hanging line under control, from which the product is removed by smoking sticks.

Calibration system & hanging system RKS 85

Price - On request

The RKS device is a universal solution for calibrating sausages and sausages in artificial and natural casings, enabling the most advanced post-processing methods to be applied to the product. The device is versatile and can be used in production facilities of any size.