Features and benefits

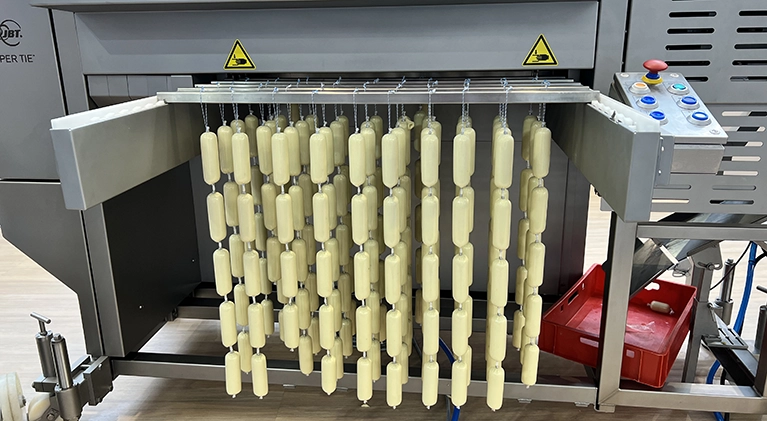

Flexible production with a high level of automation – TTStick features advanced hanging technology for even more efficient production of portioned or chain sausages.

Advantages of the system

Multifunctionality – TTStick is ideal for the efficient production of dry, smoked, vegan and raw/frozen/chilled animal feed.

High capacity and flexibility in production – the machine easily processes sausages in artificial, fiber and collagen casings.

Processing of different gauges – the basic model can process gauges from 20 mm to 120 mm with a maximum length of sausage or chain up to 800 mm.

Unmatched efficiency – TTStick is capable of producing up to 100 loops per minute, depending on the product.

Continuous production process – loops or clips can be changed by opening the housing on the belt without having to shut down the machine.

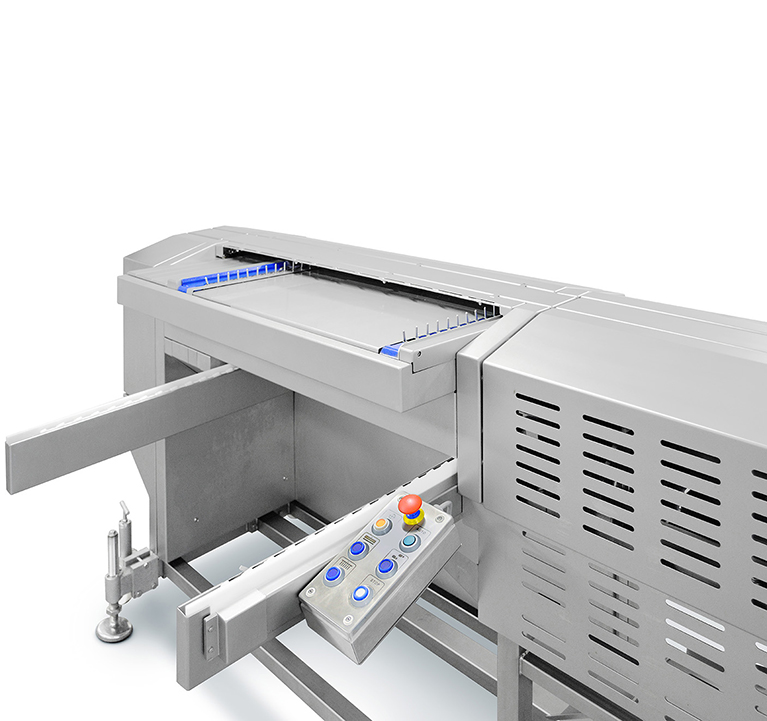

Reduced labor costs – the system is designed to be operated by a single operator, which allows you to achieve high productivity without additional labor.

User-friendly operation – the TTStick line is powered by maintenance-free servo motors and is equipped with a modern SPS control system that is operated via an intuitive touch screen.

Quick setup – all settings can be stored in the program and recalled quickly, maximizing comfort, hygiene, safety and efficiency.

Easy to clean and maintain – smooth stainless steel surfaces and robust components ensure quick and hygienic cleaning, as well as minimal maintenance, reducing downtime and overall operating costs.

Warning system – the system notifies the operator of upcoming maintenance work on the touch screen.

Advanced safety features – the system is equipped with a built-in safety monitoring system that monitors production and stops the process in the event of an equipment error, putting the TTStick, clip and syringe in standby mode.

High productivity – TTStick delivers high productivity for manufacturers by offering easy operation and minimal maintenance requirements.

Flexible handling of different sizes – the system is capable of accurately handling units of different sizes and shell types.

Easy integration – it integrates seamlessly into your existing production line, optimizing processes and providing the flexibility to meet your production goals.